Introduction for Existing Product

Model : IROVA K6L

Advantages : 1. Twin side brushes (efficient cleaning)

2. Build-in anti fall sensors

3. Simple maintenance (all-in-one dustbin)

4. Washable dustbin and filter

Function : To provide efficient cleaning in certain area

Improvement Processes

From the existing product, I did an analysis which is to improvise the product. We used Design for Manufacturing and Assembly (DFMA) analysis to lower the production costs per unit, shorter the assembly time, increase the reliability and shorter time to market.

To improvise the product, we removed the battery connector and reduced used of screws from 40 units to 38 units. This improvement have been done by doing snap fit for certain parts.

Analysis

Assembly Time

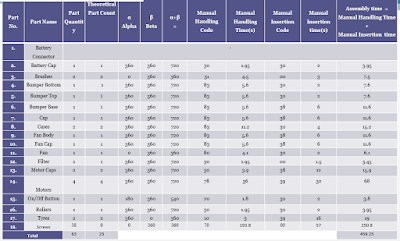

before improvement

after improvement

The assembly time is faster 16.65 seconds after the modification.

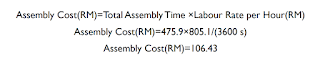

Assembly Cost

before improvement

after improvement

The assembly cost reduced RM3.72 after the improvement.

Design Efficiency

before improvement

after improvement

- Improvement succeed

- Some suggestions to improve the design efficiency are;

- Redesign more parts

- Used proper measuring tools when measure the dimension of the product