SX11-RA is a project for Proton X50. For this project, my team and I create jigs, fixtures, tables, tools, racks, and many more to help the production line. To see our works, you may click the link below;

"Dear Farahin, don't be afraid to speak up for yourself. Keep fighting for your dreams....!"

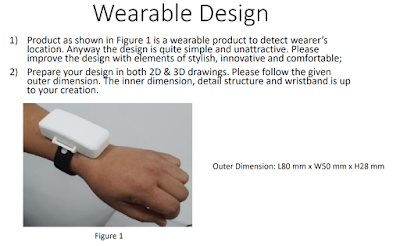

WEARABLE DESIGN

This is actually a design that I have done for an interview at one of the company in Penang. Below is an attachment of the question that I got from the company.

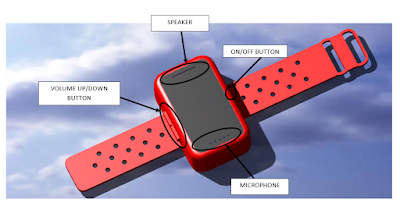

To fulfill the request, I started my design by making some research from internet. Thru the research, I known that strap is the most important item that designer should focus on in designing a wearable. This is because the users need a comfort strap for their hand. So, to get a comfort but affordable strap, I do more research on the common strap that have been used for wearable.

Based on the above summaries, I chose Polyurethane Rubber as a material for my wearable strap's design. This is because this material is the best material since it is comfort and flexible, well-fitting on hand, athletic look and also affordable.

Above is the design of the wearable that I have been done. Based on the design of the strap, there are a few holes on it. These are to make design breathable. For me the design is simple and easy to wear. User just need to slot in the strap for wear.

Here are the dimensions of the design;

MOBILE BELT CONVEYOR

Question

To design a flat belt conveyor to transfer roof tile of a single storey house. Your design criteria should be as follows:

- Motor selection – electrically / engine operated

- Belt length, width, thickness

- Pulley and shaft sizes

- Gear reduction / transfer gear box

- Angle of inclination of your belt line

- V belt for pulley

- A mobile belt design with stands

- You determine the height of system

- Raise / lower using power screw or gear (if any)

Introduction

Belt conveyor is rubber or textile structure with a belt shape closed ring. It is with vulcanized or metallic joint, used for material transportation. Belt conveyors are usually most used for transportation of solid objects and bulk materials at great speed with great distances. In my survey, mobile belt conveyor is one of the best material handling solutions for stacking any kind of bulk material when various materials has to be handled in various locations.

- High Capacity loading hopper;

- Fully tracked for on-site mobility;

- High capacity stockpile volume;

- Radial movement for bigger stock capacity;

- Remote control;

- Hopper capacity up to 10m3;

- Tracks with rubber shoes;

- ATEX zone electric equipment

Furthermore, the radial mobile belt conveyor is one of the most cost efficient and effective ways of material stockpiling. It is so mobile that it can be shifted anywhere with minimum effort.

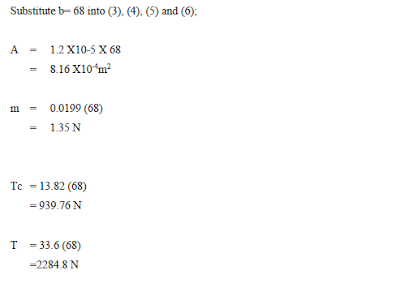

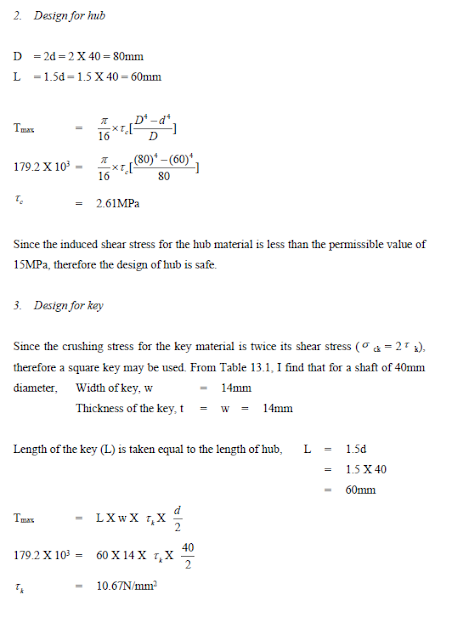

Calculations

Design

BUCKET ELEVATOR

Question

To design a bucket elevator for transporting raw material to a storage silo/garbage bin with design specifications given below:

Material to be transported: Any brittle raw material

- Intake point hopper on ground floor

- Exit/discharge point to storage/silo

- Height of bucket elevator: 30 m

- Intake hopper size with 3 m2 capacity

- Storage silo/oil 10 m tong (20000 kg)

Your design data require the followings

- Motor selection (electrically a parted)

- Bucket size with rivet position

- Chain / sprocket size and speed

- Motor – coupling – gear (if any)

- Other components as in your EPT 315

Introduction

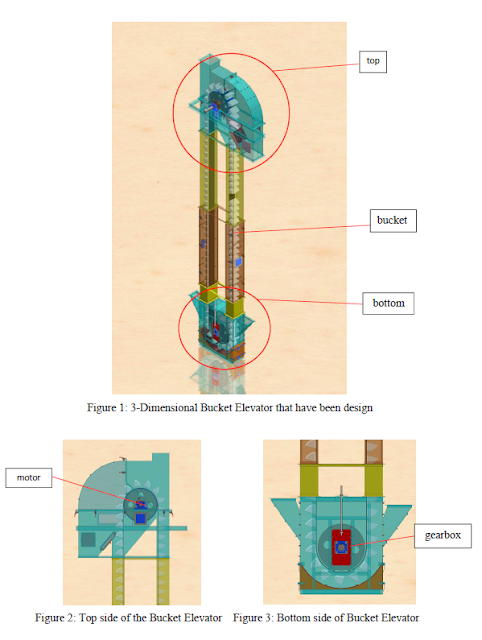

A bucket elevator, also called a grain leg, is a mechanism for hauling flow-able bulk materials (most often grain or fertilizer) vertically. It consists of buckets to contain the material, a belt to carry the buckets and transmit the pull, means to drive the belt, accessories for loading the buckets or picking up the material, for receiving the discharged material, for maintaining the belt tension and for enclosing and protecting the elevator. A bucket elevator can elevate a variety of bulk materials from light to

heavy and from fine to large lumps.

A centrifugal discharge elevator may be vertical or inclined. Vertical elevators depend entirely on the action of centrifugal force to get the material into the discharge chute and must be run at speeds relatively high. Inclined elevators with buckets spaced apart or set close together may have the discharge chute set partly under the head pulley. Since they don't depend entirely on the centrifugal force to put the material into the chute, the speed may be relatively lower. Nearly all centrifugal discharge elevators have spaced buckets with rounded bottoms. They pick up their load from a boot, a pit, or a pile of material at the foot pulley.

The buckets can be also triangular in cross section and set close to on the belt with little or no clearance between them. This is a continuous bucket elevator. Its main use is to carry difficult materials at slow speed. Early bucket elevators used a flat chain with small, steel buckets attached every few inches. While some elevators still are manufactured with a chain and steel buckets, most current bucket elevator construction uses a rubber belt with plastic buckets. Pulleys several feet in diameter are used at the top and bottom. The top pulley is driven by an electric motor.

The bucket elevator is the enabling technology that permitted the construction of grain elevators. A diverter at the top of the elevator allows the grain to be sent to the chosen bin. A similar device with flat steps is occasionally used as an elevator for humans. For example is for employees in parking garages. This sort of elevator is generally considered too dangerous to allow use by the public.

Calculations

Design

SUSTAINABILITY IN TWO HOLES PUNCHER

Introduction

Sustainability is a broad discipline, giving students and graduates insights into most aspects of the human world from business to technology to environment and the social sciences. Sustainable development is development that meets the needs of the present without compromising the ability of future generations to meet their own needs. The ability to sustain something for an indefinite period of time, without depleting the resources used to sustain it, and such that it does not damage the surroundings (environment) in which it resides. The definition of “sustainability” is the study of how natural systems function, remain diverse and produce everything it needs for the ecology to remain in balance. It also acknowledges that human civilization takes resources to sustain our modern way of life. There are countless examples throughout human history where a civilization has damaged its own environment and seriously affected its own survival chances. Sustainability takes into account how we might live in harmony with the natural world around us, protecting it from damage and destruction.

Due to ISO 14040.2 Draft: Life Cycle Assessment - Principles and Guidelines, Life Cycle Assessment (LCA) is a technique for assessing the potential environmental aspects and potential aspects associated with a product (or service) by:

- compiling an inventory of relevant inputs and outputs,

- evaluating the potential environmental impacts associated with those inputs and outputs,

- interpreting the results of the inventory and impact phases in relation to the objectives of the study.

To simplify it, Life Cycle Assessment models the complex interaction between a product and the environment from cradle to grave. For an information, the Life Cycle Assessment is also known as Life Cycle Analysis or Eco-balance. Life Cycle Assessment is have a lot of benefits. They are quantify environmental benefits of products, provide credible evidence for marketing claims, identify opportunities to improve the environmental performance of products at various points in their life cycle, inform decision‐makers in industry, government or non‐governmental organizations and also instill life cycle thinking within businesses.

Objectives of The Study

The Sustainability Assignment is actually to teach students in how to improve the sustainability of the product. Besides, students also can learn about the definition and the important of the sustainability. To undergo the sustainability process, one of the stationary at the market has been choosing, which is Two Holes Puncher. The puncher has been redesign in shape, size, materials used and way of function to make it more sustainable.

Design

\

Comparisons in Design

Material Analysis

Materials analysis is necessary to characterize and evaluate the quality and performance of materials. It supports innovation in industries such as engineering and manufacturing. Materials such as polymers, plastics, composites, metals, alloys, ceramics, paper and board have diverse properties that impact performance, therefore an understanding of your material’s properties is essential to determine if your material or product is suitable for its intended use or to rectify a failure.

Discussions

A Hole Puncher is one of the stationary that is commonly refers to the office tool. It is used to create holes in sheet paper, which is for the purpose of collecting the sheets in a binder or folder. Besides a Hole Puncher also can be refer to tools of different construction from one designed of paper. The those used are examples for the leather goods ( which generally called as a leather punch ), for cloth, for thin plastic sheeting, and also for variations of sheet metal, such as aluminum siding or metal air ducts. At the market outside, there are many kind of Holes Puncher, which are Single Hole Punch, Eyelet Punch, Multiple Holes Punch and Paper Drill. For example of Multiple Holes Puncher is Two Holes Puncher. Two Holes Puncher is choose to be used to undergo the sustainability process. The puncher chosen consists of Top Body, Bottom Body, Support Bases, Cover, Bolts and Rods.

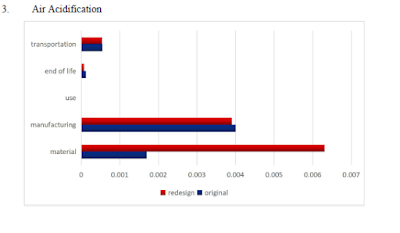

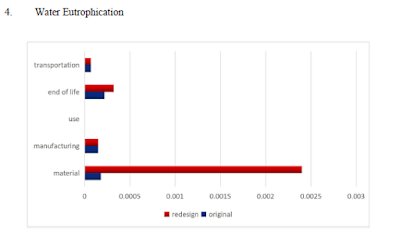

In finishing the sustainability process, Two Holes Puncher has been redesign in shape, size, materials used and way of function to make it more sustainable. The Top Body of the Two Holes Puncher that has been chosen is been redesign in it shape, which is an oval hole is applied on it. Besides, the thickness of the cover is reduced from 6mm to 4.5mm. The sustainability of the product is measured by comparing the material used to make the Top Body, Bottom Body and Base Supports material, which are Carbon Steel Sheet, Annealed Stainless Steel and Stainless Steel Sheet.

Based on the comparisons of the design of the both Two Holes Punchers, the Redesign Two Holes Puncher is better. This is because the environmental impact of the Carbon Footprint, Total Energy Consumed, Air Acidification and the Water Eutrophication for the redesign puncher are higher than the original one. For example, at the Carbon Footprint, the environmental impact of material for redesign puncher is 1.3kg CO2e while for the original puncher, the environmental impact of material is 0.688 CO2e. So, it is true that the size and the shape of the any product effect it sustainability.

By comparing the materials used by the Two Holes Punchers, the Carbon Steel Sheet and the Annealed Stainless Steel are both the better materials compared to the Stainless Steel Sheet. The environmental impact of the Carbon Footprint, Total Energy Consumed, Air Acidification and the Water Eutrophication for the Carbon Steel Sheet and the Annealed Stainless Steel are sharing the same values, which are mostly higher compared to the Stainless Steel Sheet. Due to the results, we can know that the differences in materials of any product will effect the sustainability value of the product even though the size and the shape are same.

Therefore, the Redesign Two Holes Puncher with the Carbon Steel Sheet or the Annealed Stainless Steel material is the recommended puncher. This is because the puncher is better in sustainability, so that it will give benefits to the environment, society and economy.

Conclusions

Sustainability is actually used to describe many different approaches toward improving our way of life. There are some views of sustainability. Sustainability means reducing our harm on environment and ultimately reversing the harm we have already caused. Besides, sustainability means renewing resources at a rate equal to or greater than the rate at which they are consumed. Furthermore, sustainability can be definition as taking the long term view of how our actions effect generations and making sure we don’t deplete resources or cause pollution at rates faster than the earth is able to renew them.

From the result, I can analyze that the materials used, the shapes, the size will effect the sustainability of the product. Every changes make will effect the end life of the product. Besides, I can conclude that sustainability is occurring when environment, society and economy are thriving. A healthy economy is actually depending on a healthy society, while both of which rely on a healthy environment.

There are many benefits that can be obtain from the sustainability process. First is environmental sustainability. The environmental sustainability is actually good for financial. An intelligent approach to environmental sustainability that incorporates investor demands can help future-proof investment and engagement from shareholders. Besides is the environmental sustainability is also can manage risks and increase the opportunities to growth in business , which is not just in terms of improved financial performance but also from attracting and retaining the brightest talent and increased levels of innovation. Second is sustainable society. Sustainable society is the one that can continue indefinitely. Its level of consumption reflect environmental and resources balance. It assure its citizens equality, freedom and a healthy standard living thing. The economic sustainability the ability to support a defined level of economic production indefinitely.

So, in the nutshell, everyone should be build the sustainability style in their life encourage toward the environmental, society and the economic. Therefore, I am encourage all to emphasis in apply the sustainability in their life since there are many advantages that can help our own self.

FIRE PREVENTION SYSTEM FOR POT

Objective

To prevent fire from occur at the kitchen due to the people carelessness.

Scope and Limitation

This investigatory project covers the process on how to prevent the fire from happen in the kitchen at home. For this mini project, the study is more focused on the pot. This fire prevention system is actually created for housewives. This is to make the housewives alert with the situation when they are cooking and doing the other works at the same time. For this project, buzzer will buzz when the smoke detector, MQ2 detect the smoke and continued buzzing until no more smoke is detected. Based on my study, MQ2 is actually can detect the smoke in range of 0.5 to 1 meters.

Apparatus

- Arduino UNO Board

- 16X2 LCD

- Smoke Sensor Module (MQ2)

- LED (1 yellow and 1 red)

- Buzzer

- Breadboard

- Connecting Jumper Wires

Flow Chart

System

Code

#include<LiquidCrystal.h>

LiquidCrystal lcd(7,6,5,4,3,2);

int redLed = 10;

int greenLed = 12;

int buzzer = 8;

int smokeA0 = A0;

//Your threshold value

int sensor Thres = 200;

void setup()

{

pinMode(redLed,OUTPUT);

pinMode(buzzer,OUTPUT);

pinMode(smokeA0,INPUT);

Serial.begin(9600);

lcd.begin(16,2);

}

void loop()

{

int analogSensor = analogRead(smokeA0);

Serial.print("PinA0:");

Serial.printIn(analogSensor);

lcd.print("Smoke Level:"); lcd.print(analogSensor-50);

//Checks if it has reached the threshold value

if (analogSenso-50>sensorThres)

{

digitalWrite(redLed,HIGH);

lcd.setCursor(0,2);

lcd.print("Alert....!!!!");

digitalWrite(12,LOW);

tone(buzzer,1000,200);

}

else

{

digitalWrite(redLed,LOW);

digitalWrite(12,HIGH);

lcd.setCursor(0,2);

lcd.print(".....Normal.....");

noTone(buzzer);

}

delay(500);

lcd.clear();

}

Data Analysis

The LED is lighting and the buzzer is buzzing when smoke detector, MQ2 detect the smoke.

ROBOT VACUUM CLEANER

Introduction for Existing Product

Model : IROVA K6L

Advantages : 1. Twin side brushes (efficient cleaning)

2. Build-in anti fall sensors

3. Simple maintenance (all-in-one dustbin)

4. Washable dustbin and filter

Function : To provide efficient cleaning in certain area

Improvement Processes

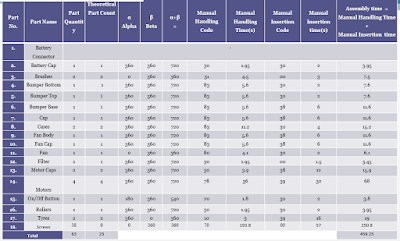

From the existing product, I did an analysis which is to improvise the product. We used Design for Manufacturing and Assembly (DFMA) analysis to lower the production costs per unit, shorter the assembly time, increase the reliability and shorter time to market.

To improvise the product, we removed the battery connector and reduced used of screws from 40 units to 38 units. This improvement have been done by doing snap fit for certain parts.

Analysis

Assembly Time

before improvement

after improvement

The assembly time is faster 16.65 seconds after the modification.

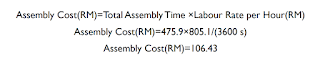

Assembly Cost

before improvement

after improvement

The assembly cost reduced RM3.72 after the improvement.

Design Efficiency

before improvement

after improvement

- Improvement succeed

- Some suggestions to improve the design efficiency are;

- Redesign more parts

- Used proper measuring tools when measure the dimension of the product

Subscribe to:

Comments (Atom)